Stel ons

uw vraag!

Wanneer kies ik voor

een (type) dolly en waarom?

Het diepbed van een ‘dieplader’ is lager dan het asstel; de laadvloer ligt ‘verdiept’ ten opzichte van het asstel. Deze lagere laadvloer zorgt voor een lagere doorrijhoogte, wat met name onder viaducten en tunnels tot zijn recht komt.

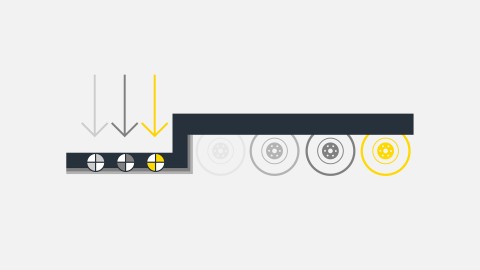

Wanneer men een oplegger met meer laadvermogen wil hebben, plaatst men normaal gesproken ‘een asje meer’ onder de laadvloer. Het is natuurlijk iets te simpel gesteld, maar écht veel spannender is het niet. Bij diepladers ligt ‘het laadvermogen’ ingewikkelder. De laadvloer is lager dan de hoogte van het asstel: ‘een asje meer’ onder de laadvloer gaat niet i.v.m. de inbouwhoogte van de as. Het laadvermogen vergroten door alleen het asstel uit te voeren met meer assen, werkt in de praktijk maar tot een 3-assige dieplader. Dit heeft te maken met de gewichtsverdeling van een dieplader.

Gewichtsverdeling

Als men alléén aan de achterzijde van het diepbed meer assen monteert, zal de dieplader niet alleen aan de achterzijde zwaarder worden, maar ook alleen aan de achterzijde meer laadvermogen krijgen. Het zwaartepunt van de dieplader zal zich dus meer richting het asstel verplaatsen naar mate er meer assen gemonteerd zijn. Dit is ook het geval wanneer je een semi dieplader uitschuift, lees hier meer.

Algemeen geldt dat men aan beide zijden van de laadvloer de laadcapaciteit dient te vergroten, als men het laadvermogen van een dieplader wil verhogen.

(Uiteraard zal dan ook het chassis versterkt moeten worden.)

Laadcapiciteit

Voor het verhogen van de laadcapaciteit aan de achterzijde van de laadvloer is er maar 1 mogelijkheid: meer assen/aslijnen + meer staal.

Voor het verhogen van de laadcapaciteit aan de voorzijde van de laadvloer zijn er 4 opties, met elk hun eigen voor- en nadelen:

Optie 1: De ‘’meer assige trekker’’

Voordelen

+ korte combinatie

+ Laag eigengewicht van combinatie

+ Eenvoudig te bedienen

+ Eenvoudig te besturen

+ Hulpbesturing op alle assen van de dieplader

Nadelen

- Lange + zware zwanenhals

- Zwaar uitgevoerde laadvloer i.v.n. hefboom nek

- Kostbare trekker (aanschaf als exploitatie)

- Afhankelijkheid van een bepaalde trekker

- Beperkt tot max 6-assige trekker

- Grote draaicirkel

- Later alleen als combinatie te verkopen

- Niet in elk land toegestaan

Optie 2: De Jeep-Dolly:

(Dolly zit tussen de trekker en de zwanenhals in)

Een jeep dolly is een extra as die je kan plaatsen onder de zwanenhals. Hiermee creëer je als het ware een extra as voor je truck. Dankzij deze extra as kun je weer laadvermogen creëren en kun je dus zwaardere ladingen transporteren. Ook wordt de koppelingsdruk beter verdeeld tussen de truck en de zwanenhals van de dieplader. Het grote voordeel van de jeep dolly is dat hij compact is en eenvoudig af te koppelen. Doordat de jeep dolly is voorzien van een schotel, werkt het precies hetzelfde als bij het aan- en afkoppelen van een truck en oplegger. Daarnaast zorgt de compactheid ervoor dat je combinatielengte niet veel langer wordt en dat je combinatie makkelijk kan draaien. Ook is de jeep dolly gering in eigengewicht, wat het totale combinatiegewicht niet extreem doet stijgen.

Voordelen

+ Korte combinatie

+ Laag eigengewicht van combinatie

+ Kleine draaicirkel door dubbel draaipunt

+ Standaard trekker

+ Lage “Cost Of Ownership”

+ Lage aanschafwaarde

+ Eenvoudig te bedienen

+ Bij lichtere vrachten hoeft hij niet gebruikt te worden

Nadelen

- Hoge koppelingshoogte zwanenhals

- Afhankelijkheid van de Jeep Dolly

- Achteruitrijden vergt oefening

- Beperkt tot Max. 4 assige Jeep Dolly

- Toegestane aslasten verschillen per land

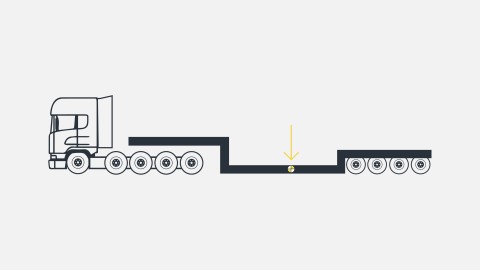

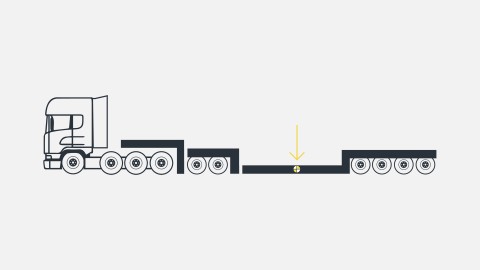

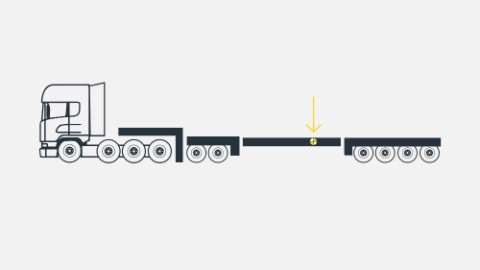

Optie 3 en 4: De dolly:

(dolly zit tussen de zwanenhals en het diepbed in)

Een dolly is als het ware een extra asstel dat tussen de zwanenhals en het diepbed in zit. Hiermee verhoog je het laadvermogen en vergroot je de laadvloer. Dit laatste punt is uniek bij een Broshuis pendelas dieplader. Dit omdat je op onze dolly kan en mag laden. Dankzij de dolly wordt het gewicht beter verdeeld tussen de kop en de assen. Deze betere gewichtsverdeling maakt het mogelijk om meer diversiteit aan ladingen mee te kunnen nemen. Deze dolly is in twee varianten, een vaste dolly aan de nek, of een uitneembare dolly.

Optie 3: Vaste dolly aan de nek

Voordelen

+ Normale koppelingshoogte zwanenhals

+ Standaard trekker

+ Toegestane aslasten ten minste 12T/ Lijn

+ Lichter uitgevoerd diepbed

+ Eenvoudig te besturen

+ Assen dolly liftbaar

+ Hulpbesturing op alle assen van de dieplader

Nadelen

- Langere combinatie

- Hoger eigengewicht combinatie

- Grotere draaicirkel

- Hogere “cost of ownership”

- Hogere aanschafwaarde

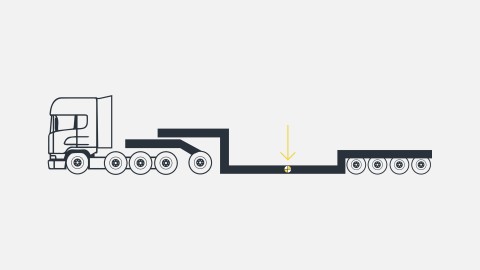

Optie 4: Uitneembare dolly

Voordelen

+ Normale koppelingshoogte zwanenhals

+ Dieplader ook te gebruiken zonder dolly

+ Standaard trekker

+ Toegestane aslasten ten minste 12T/ Lijn

+ Lichter uitgevoerde laadvloer

+ Eenvoudig te besturen

+ Assen dolly liftbaar

+ Hulpbesturing op alle assen van de dieplader

+ Kan omgebouwd worden naar semi dieplader

+ Mogelijkheid tot koppelen van meer aslijnen

Nadelen

- Lange combinatie

- Hoger eigengewicht combinatie

- Grotere draaicirkel

- Hogere “cost of ownership”

- Hogere aanschafwaarde

- Bediening vergt oefening

- Complexer hydrauliek-, elektrisch-, remsysteem.

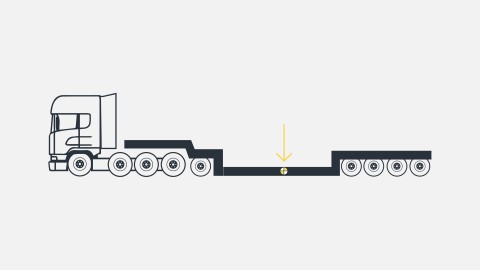

Semi Optie: dolly op een Semi dieplader

In onze 100T Range is het ook mogelijk om een dolly op een semidieplader met SL- of PL-as te plaatsen. In dat geval kunt u de dolly gebruiken voor gewichtsverdeling wanneer de semi is uitgeschoven. Bij het uitschuiven van een semi verplaatst het zwaartepunt zich naar de voorzijde van de oplegger. Door een dolly tussen de zwanenhals en het assenstel te bevestigen, vergroot u het laadvermogen aan de voorzijde en verbetert u de positie van het zwaartepunt.

Daarnaast geeft het ook flexibiliteit bij het configureren van de oplegger. Ingeschoven geeft de dolly extra laadvermogen aan de oplegger en de dolly kan worden verwijderd als er minder laadvermogen nodig is om een kortere combinatie te creëren.

Voordelen

+ Normale koppelingshoogte zwanenhals

+ Dieplader ook te gebruiken zonder dolly

+ Standaard trekker

+ Toegestane aslasten ten minste 12T/ Lijn

+ Lichtere semi

+ Eenvoudig te besturen

+ Assen dolly liftbaar

+ Hulpbesturing op alle assen van de semi dieplader

+ Mogelijkheid tot koppelen van meer aslijnen

Nadelen

- Lange combinatie

- Hoger eigengewicht combinatie

-PL-semi-low-loader-2.png)

-SL-semi-low-loader.png)