Ask us

your question!

Quality and durability

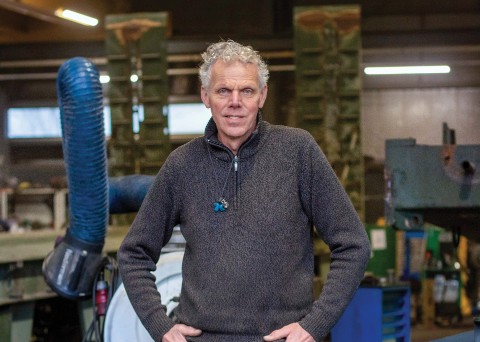

At Broshuis, everything revolves around quality and durability. Our trailers leave the factory after thorough testing and are built to last for decades. This is clearly demonstrated in the Tropco refurbishment project (Defense trailers), led by our Production Manager for Repairs, René Neleman. What makes this project special is René’s personal connection with Tropco: twenty years ago, he was involved in the original construction, and now he is ensuring that the same trailers are being refurbished—ready for another twenty years of service.

René began his career at Broshuis in the final assembly and was soon involved in the first military order in 1992. His technical insight and attention to detail led to his involvement in the Tropco order in 2005. At that time, processes were different than they are today: drawings were less detailed, and René would personally mark the plans where mounting plates needed to be welded for the installation of electrical systems and lighting. This required a solution-oriented approach, making the work both challenging and valuable. One of the biggest challenges with the Tropco trailers was the limited space for brake lines, hydraulics, and electrics. René found an innovative solution by proposing that these components be integrated into the trailer's main beam.

Refurbishment shows craftsmanship

What started as an innovative solution has proven to be a resounding success two decades later. René, now the Production Manager for Repairs, is overseeing the refurbishment of the Tropco trailers and sees the results of the work from back then. "During the refurbishment, we discovered that everything we placed in the main beam at that time is still in excellent condition," says René. What stands out as well is the rust formation on certain parts. "At the time, the decision was made not to metallize these trailers. Yet, this proves that the trailers have operated effortlessly for twenty years with the techniques chosen back then. Since then, we've further developed our techniques and quality standards."

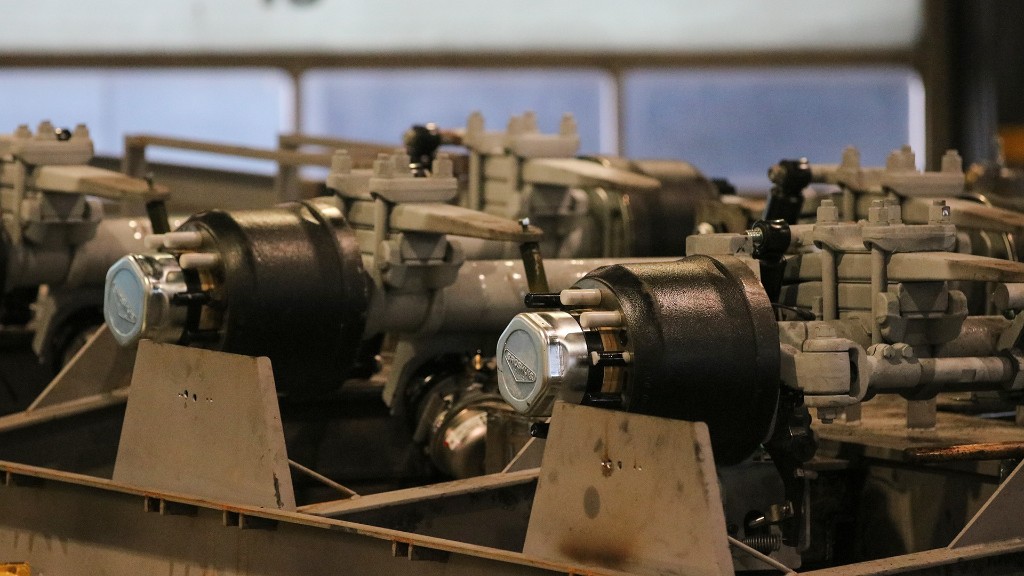

René’s department is responsible for stripping and disassembling the 4- and 7-axle trailers. After stripping, the trailers are blasted to remove old paint and rust. The necessary modifications are then made, and the axles are reassembled.

For optimal protection, the trailers are coated with a zinc-aluminium alloy (metallizing), followed by a two-component epoxy primer and a 2K top coat. After this thorough refurbishment, the trailers leave the factory as virtually new trailers. “All technical components have been replaced, and because they are blasted, metallized, and coated, they will last for many more years,” says René. “I don’t expect to see these trailers again in my career, as they are good for another 20 years!” The refurbished trailers are expected to be delivered to the Dutch Ministry of Defense in May.

Proud of growth and innovation

René is proud of the growth Broshuis has experienced. “We’ve gone from a small company to a large one with seven halls and around 500 employees. It’s wonderful to see how our technical innovations have developed through the knowledge and experience we've gained over the years.” With 38 years of Broshuis experience, René is a living testament to how expertise and innovation contribute to the long lifespan and quality of our trailers.