Ask us

your question!

cutting-edge technology

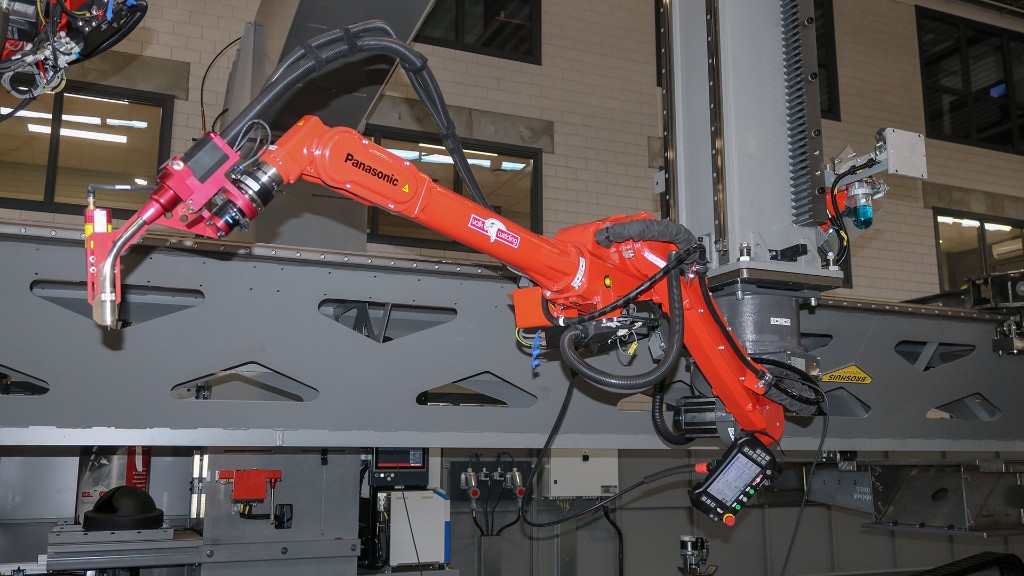

At Broshuis, we continuously strive to improve and ensure the quality of our products. We do this not only through experience and craftsmanship, but also by strategically investing in cutting-edge technology. A recent example is the commissioning of our new welding robot, delivered by Valk Welding. The system is now fully operational and successfully integrated into our daily production.

Collaboration, innovation, and craftsmanship

The implementation of our new welding robot is the result of close cooperation across departments. From technical specifications to fabricating essential components. For example, we designed and built the welding bridge and connectors ourselves. Every aspect reflects craftsmanship and a tailored fit with our production flow. This robot is not just a machine, but a smart reinforcement for our team. The blend of automation and hands-on expertise ensures even more precision, efficiency, and consistent quality.

Looking ahead, the cooperation between man and machine will remain vital. No matter how advanced the technology, craftsmanship is what truly makes the difference.

Automating our production process

The new welding robot is more than just a technical upgrade. It’s a major milestone in automating our production process. The system includes two separate welding robots that work in cooperation on trailer modules. These robots are connected to a welding bridge via product connectors that move along rails, positioning the product during welding. The welding bridge is positioned between two Valk Welding manipulators and can be adjusted both horizontally and vertically for the ideal working position. This flexibility allows the robots to simultaneously weld different parts of the module, significantly improving the efficiency and accuracy of the production process.

The robots have been named Echo and Foxtrot, following the legacy of Alfa, Bravo, Charlie, and Delta who have already been in use at Broshuis for a longer time.

Ready for the future

With Echo and Foxtrot now in action, Broshuis has made a significant leap forward in advanced, efficient production. This project highlights the importance of collaboration and innovation in our company. Thanks to the efforts of our partner Valk Welding and our internal teams, we’re proud of what’s been achieved and well-prepared for the future. We look forward to maximising the benefits of this new welding system, and elevating our quality even further.