Ask us

your question!

Securing loads

Within Europe, there used to be major discrepancies in national standards and laws regarding securing loads. That is why it was decided in the EU to establish this in ‘EN standards’ to ensure better uniformity/equivalency for safety. The standard was drawn up in the year 2000 and took effect as of 1 January 2004.

To give every country the opportunity to implement this standard nationally without having to modify all the “older” transport equipment immediately, a timespan of 10 years was set for redundancy. This created a gradual transition.

In short, this means that as of 1 January 2014, all EU countries must satisfy this standard.

In Europe, three standards are very important:

- EN 12640: Securing of cargo on road vehicles

Lashing points on commercial vehicles for goods transportation. Minimum requirements and testing

- EN 12195-1: Load restraining on road vehicles

Calculation of securing forces

EN 12195-2: Load restraint assemblies on road vehicles

Web lashing made from man-made fibres

EN 12195-3: Load restraint assemblies on road vehicles

Lashing chains

- 3- VDI 2700 (Dld)

Ladungssicherung auf Straßenfahrzeugen Großraum- und Schwertransporte

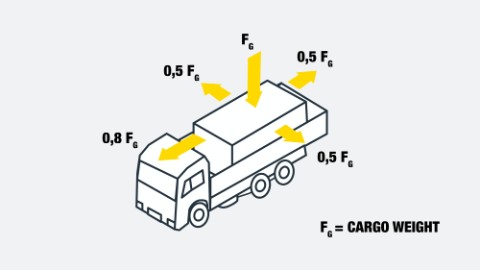

Loading conditions

When driving on the road, four types of forces can be exerted on the load. The load must therefore be secured according to the ‘EN standards’ such that the load is secured against them.

- In the drive direction: Maximum 0.8 FG = 80 per cent of the cargo weight

- In lateral direction: Maximum 0.5 FG = 50 per cent of the cargo weight

- Backwards: Maximum 0.5 FG = 50 per cent of the cargo weight

Conditions for transport equipment

For the transporter to meet these conditions, the equipment used must of course also meet a number of conditions. These are laid down in the ‘EN-12640 standard’. Briefly, this standard amounts to enough lashing points being required in the trailer to be able to adequately secure the total load capacity of the vehicle.A vehicle with a load capacity over 12T must at least satisfy the following requirements:

- The minimum strength of the lashing point must be 2T.

- The first lashing point may be positioned a maximum of 500 mm from the front bulkhead, and the last lashing point may be at a maximum of 500 mm from the tail end.

- All the intervening lashing points may be spaced a maximum of 1,200 mm from each other (above the axles a maximum of 1,500 mm)

- The lashing points must be able to pivot a minimum free angle of 30° relative to the cargo bed.

In practice, this means that according to the ‘EN-standard’, a trailer with a cargo length of 13,600 mm must be have 22 lashing points.

(13,600 mm – 1,000 mm (2x 500 mm) = 12,600 mm: 1,200 mm = 10.5 lashing points on each side)

It is of course a major advantage if the lashing points in a semi-trailer are also TÜV certified. During an inspection, the driver then only has to present their certificate to the inspection institution and there does not have to be any discussion about whether or not the lashing points are suitable. It is also a major advantage if the side bar, the front bulkhead and the form fitting equipment such as stock blocks and rungs are certified.

Conditions for lashing material

Once all these points are seen to, of course you need to use tie-down straps and chains that also meet the ‘EN standard’. The following ‘EN standards’ are relevant to the fastening equipment.

- EN 12195-2 Web lashing

- EN 12195-3 Chains

This means for example that these must be provided with a legible label at all times. A new (even unused) tie-down strap that has the label torn off may not legally be used!

Further, it is for example necessary to check chains for the force that they may/can bear. If lashing points are present in the trailer that can bear a maximum of 10T, there is of course no point in using 16T chains with them. The inspection institutions always look at the weakest link, and in this example that is the 10T of the lashing point.

Driver conditions

As a final point, it is also very important that the driver knows the standards the equipment must meet and how to secure the cargo in compliance with the law. There are a number of courses for this that also count toward the Code 95 driving licence endorsement. There are two variants for securing loads: the course that focuses on “normal” transport (Tautliner, cooler), and the course that focuses on securing loads in special transport. Which course is more relevant therefore depends on the branch of transport.